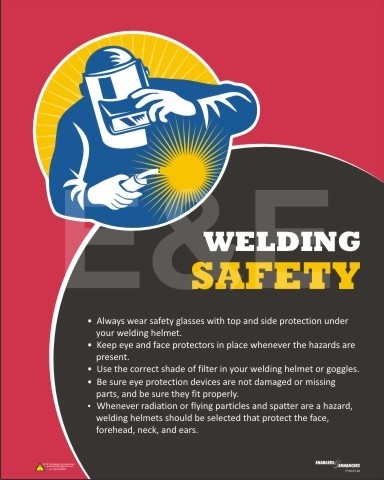

Welding Safety

Welding injuries, from minor flash burns to eye injuries, can be painful and cause disfigurement or career-ending disabilities. Wearing the proper PPE is an easy way welders can protect themselves against these risks and preserve their livelihood. Unfortunately, overconfidence leads welders to think they are immune to such injury, or they may choose not to use PPE because it is too expensive or the job is too small. Some welders under-protect themselves because they feel the PPE is too warm or restrictive to wear. Fortunately, workers now can find new PPE garments made of lightweight materials that wick away sweat to stay comfortable. Welders now have many options in materials, flame-retardant traits, fabric weight and accessories to suit up for the job. Welding helmets should be equipped with the proper filter lens in either a passive or an autodarkening style to shield against the arc’s bright light. Remember that ANSI Z87.1 lists welding helmets as secondary eye protection that must be used with the primary protection provided by safety glasses or goggles. Airborne hazards should also be assessed and the necessary engineering controls implemented to maintain acceptable exposure levels using ventilation, fans or fume extractors.

- rn39c90ee4269946791bdfe8d9657e77f7.jpg

- 6xbc8644fd4f5a945cb60e72fe4205e5b1.jpg

Videos

References

http://www.ishn.com/articles/10-neglected-construction-safety-concerns

Pictures:

http://static.emedco.com/media/catalog/product/Wallcharts-WC-WE-ba.jpg

http://www.5squalityposters.com/images/product_images/product_large_443.jpg

Video:

http://www.youtube.com/watch?v=AVJYGHAA57Q

http://www.youtube.com/watch?v=sxh8uUPljhY