Food Safety - Hierarchy Of Food Safety Management System

Good Manufacturing Practices 5s of Good Housekeeping

Hierarchy of Food Management System

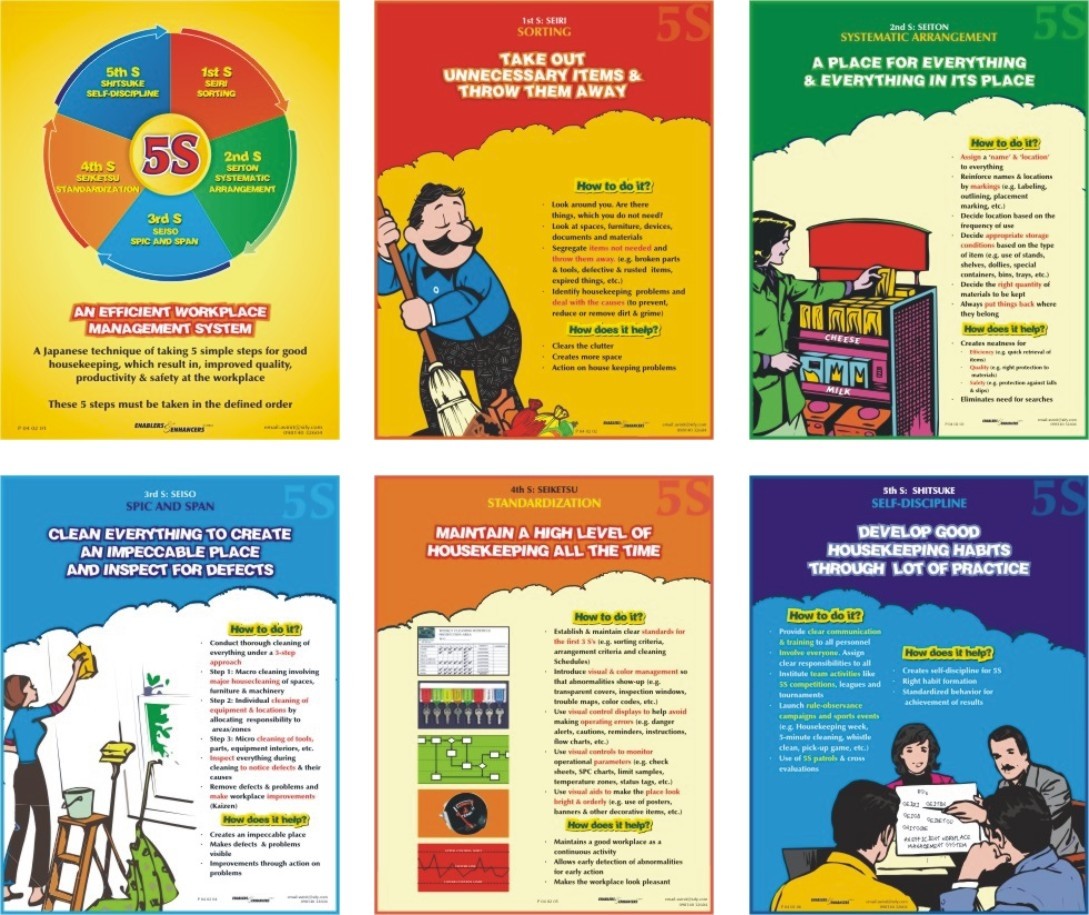

What is 5S

Kaisen – Japanese philosophy or practice of continuous improvement from the chief to the assembly line worker

Japanese

English

Seiri

Sort

Seiton

Set in order / Systematize

Seiso

Sweep / Shine

Seiketsu

Standardize / Sanitize

Shitsuke

Sustain / Self-Discipline

Quality assurance system aimed at ensuring that products are consistently manufactured, packed, repacked or held to a quality appropriate for the intended use. It is concern with manufacturing and quality control procedures.

SINK DISHWASHING

1. Wash - warm water & dish washing soap

2. Rinse - Clean Water at least 43 (110 f)

3. Disinfect - Clean water plus Disinfectant at 24 c (75-f) for 45 second

4. (Bleach) - Chlorine 100 ppm quats 200ppm iodine 25ppm

7 Principles of HACCP

- Conduct hazard analysis

- Determine the critical control point

- Establish critical limits

- Establish a system to monitor control of the CCP - Identify corrective actions.

- Verify that the system works.

- Establish procedures for record keeping and documentation

ISO 22000 Hazard Analysis Critical Control Points Sanitation Standard Operating Procedures

ISO 22000

- Compliance with the Codex HACCP principles

- Harmonize voluntary to international standards

- Provide an auditable standard

- Use of internal audits

- 3rd party certification

- Provide communication of HACCP concepts

6 Mandatory Procedures

- Control of documents

- Control of records

- Corrections (control of non-conforming products)

- Corrective actions

- Recall (this includes traceability) - Preventive actions

- Internal Audit

Hierarchy of Food Management System

What is 5S

Kaisen – Japanese philosophy or practice of continuous improvement from the chief to the assembly line worker

Japanese

English

Seiri

Sort

Seiton

Set in order / Systematize

Seiso

Sweep / Shine

Seiketsu

Standardize / Sanitize

Shitsuke

Sustain / Self-Discipline

Quality assurance system aimed at ensuring that products are consistently manufactured, packed, repacked or held to a quality appropriate for the intended use. It is concern with manufacturing and quality control procedures.

SINK DISHWASHING

1. Wash - warm water & dish washing soap

2. Rinse - Clean Water at least 43 (110 f)

3. Disinfect - Clean water plus Disinfectant at 24 c (75-f) for 45 second

4. (Bleach) - Chlorine 100 ppm quats 200ppm iodine 25ppm

7 Principles of HACCP

- Conduct hazard analysis

- Determine the critical control point

- Establish critical limits

- Establish a system to monitor control of the CCP - Identify corrective actions.

- Verify that the system works.

- Establish procedures for record keeping and documentation

ISO 22000 Hazard Analysis Critical Control Points Sanitation Standard Operating Procedures

ISO 22000

- Compliance with the Codex HACCP principles

- Harmonize voluntary to international standards

- Provide an auditable standard

- Use of internal audits

- 3rd party certification

- Provide communication of HACCP concepts

6 Mandatory Procedures

- Control of documents

- Control of records

- Corrections (control of non-conforming products)

- Corrective actions

- Recall (this includes traceability) - Preventive actions

- Internal Audit

- em085005c807481ed638ebba5df4307aae.jpg