Equipment Safety Checklist

If you run a business where employees deal with machinery, the safety of your employees is a vital consideration. You must have training and practices in place that promote safe operation of all equipment. A safe working environment saves you money and helps your employees to feel secure. Make your safety preparation as thorough as possible with a detailed checklist for equipment safety. Your checklist will help you to develop a systematic plan for the maintenance your business requires to operate safely.

Equipment Inventory

Your checklist for equipment safety should include a list of all machinery in your workplace. Record the location of each piece of equipment and a brief physical description. Also note the potential safety problems this equipment could cause, and how to account for these dangers.

Training

For each piece of equipment, determine whether adequate safety training has been provided to each person who uses it. Determine if further training must be scheduled to bring employees up to speed on the risks and precautions of each piece of equipment. Ensure that the training is properly documented, with signatures from all involved that the proper training has taken place.

Instructions

If the equipment in your workplace came with written instructions, ensure that each employee has a copy of them. Verify that everyone has read and understood the sections of the instruction manual that explain dangers and warnings about the use of the equipment.

Environment

Ensure that all equipment is being used in a safe location. Some equipment can only be used in well-ventilated areas. Some must only be stored in a room that falls within a specified temperature range. Consider fire hazards near the equipment that may cause danger. Some equipment can be dangerous to use in damp conditions.

Signs

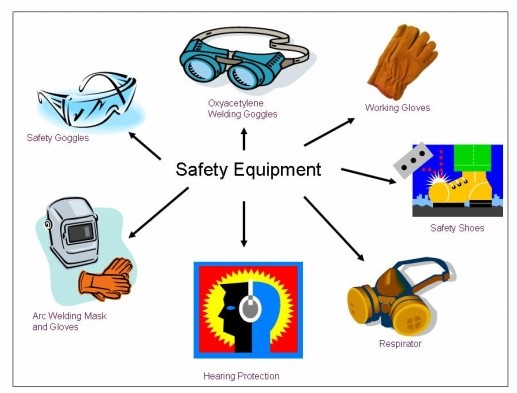

Place easily visible warning signs and labels near each piece of equipment in your workplace. If only certain people are authorized to use a piece of machinery, post the list of authorized personnel near it. Also post the required safety gear that must be worn near the equipment. Post safety instructions and cautions where employees will easily notice them before using the equipment. Clearly label all storage containers with contents and safety instructions.

Schedule

Every workplace must schedule routine inventory and maintenance on a regular basis. Each piece of machinery must be checked to ensure it is in working condition. Safety standards must be checked. Warning labels and instructions must be updated to ensure that they are easily visible and understood. Safety training must be repeated regularly to ensure that employees retain the information. The maintenance schedule will vary widely based on the types of equipment you use. Make safety a priority in your workplace by following a regular routine of safety maintenance and training.

Equipment Inventory

Your checklist for equipment safety should include a list of all machinery in your workplace. Record the location of each piece of equipment and a brief physical description. Also note the potential safety problems this equipment could cause, and how to account for these dangers.

Training

For each piece of equipment, determine whether adequate safety training has been provided to each person who uses it. Determine if further training must be scheduled to bring employees up to speed on the risks and precautions of each piece of equipment. Ensure that the training is properly documented, with signatures from all involved that the proper training has taken place.

Instructions

If the equipment in your workplace came with written instructions, ensure that each employee has a copy of them. Verify that everyone has read and understood the sections of the instruction manual that explain dangers and warnings about the use of the equipment.

Environment

Ensure that all equipment is being used in a safe location. Some equipment can only be used in well-ventilated areas. Some must only be stored in a room that falls within a specified temperature range. Consider fire hazards near the equipment that may cause danger. Some equipment can be dangerous to use in damp conditions.

Signs

Place easily visible warning signs and labels near each piece of equipment in your workplace. If only certain people are authorized to use a piece of machinery, post the list of authorized personnel near it. Also post the required safety gear that must be worn near the equipment. Post safety instructions and cautions where employees will easily notice them before using the equipment. Clearly label all storage containers with contents and safety instructions.

Schedule

Every workplace must schedule routine inventory and maintenance on a regular basis. Each piece of machinery must be checked to ensure it is in working condition. Safety standards must be checked. Warning labels and instructions must be updated to ensure that they are easily visible and understood. Safety training must be repeated regularly to ensure that employees retain the information. The maintenance schedule will vary widely based on the types of equipment you use. Make safety a priority in your workplace by following a regular routine of safety maintenance and training.

- 0yc72d871f92d6a2a873744949e2d7b83a.jpg